Do you want to work in the mechanical design industry?

Do you have a dream of working as a mechanical design engineer?

Then this blog is for you.

I have put together a list of the 5 most essential skills every design engineer should have to thrive in their career.

1. CAD

CAD - Computer-aided Design

Use of Computers/Workstations to create, modify, analyze and optimize your Design

Various CAD Software to choose from to start your learning process

- CATIA

- SIEMENS NX

- creo

- SOLIDWORKS

- SOLID EDGE

- AUTODESK- AUTOCAD

![RH Design - 5 Most Important Skills For Every Mechanical Design Engineer To Get a Dream Job & Career RH Design [dcZ2jAoa0ok - 1046x588 - 1m15s].png](https://cdn.hashnode.com/res/hashnode/image/upload/v1660034395677/yjpVGFn7T.png?auto=compress,format&format=webp)

Each one of this software is primarily and majorly used to create two designs in 2 phases;

- 3d CAD modeling and

- 2d CAD drawings

![RH Design - 5 Most Important Skills For Every Mechanical Design Engineer To Get a Dream Job & Career RH Design [dcZ2jAoa0ok - 1046x588 - 1m33s].png](https://cdn.hashnode.com/res/hashnode/image/upload/v1660034787996/rXu41BBLq.png?auto=compress,format&format=webp)

You start with rfqs and various proposals in 3d modeling for your initial design which goes on to mature multiple iterations and modifications to fulfill all customer requirements.

Once your design is a phase you move on to create 2d drawings which involve creating various views and sections for your product either in the 1st angle or 3rd angle projections.

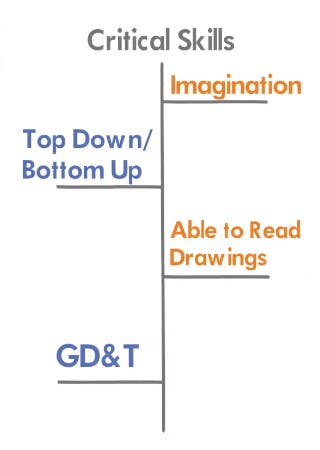

Critical Skills

Here are some critical skills Engineers need to have to create this design successfully.

Imagination every design engineer should be able to visualize the concept of design and product top-down or bottom-up approach.

Design Engineers follow a top-down approach bottom-up approach or a mix of both while working on complex design projects.

Ability to read drawings design engineers work with drawings and the ability to read ranks is crucial for engineers.

GD&T could be considered as a language of engineers through which designers communicate the designs with other engineers to help create a successful product.

2. Mechanics

Mechanics - The study of forces on a body or a system and their behavior under those forces.

Design engineers need to have the ability to understand the forces which would be applied to the product to successfully design.

Strength mechanics has been divided into two branches

- Statics & 2. Dynamics.

Dynamics is further divided into

- kinetics & 2. kinematics

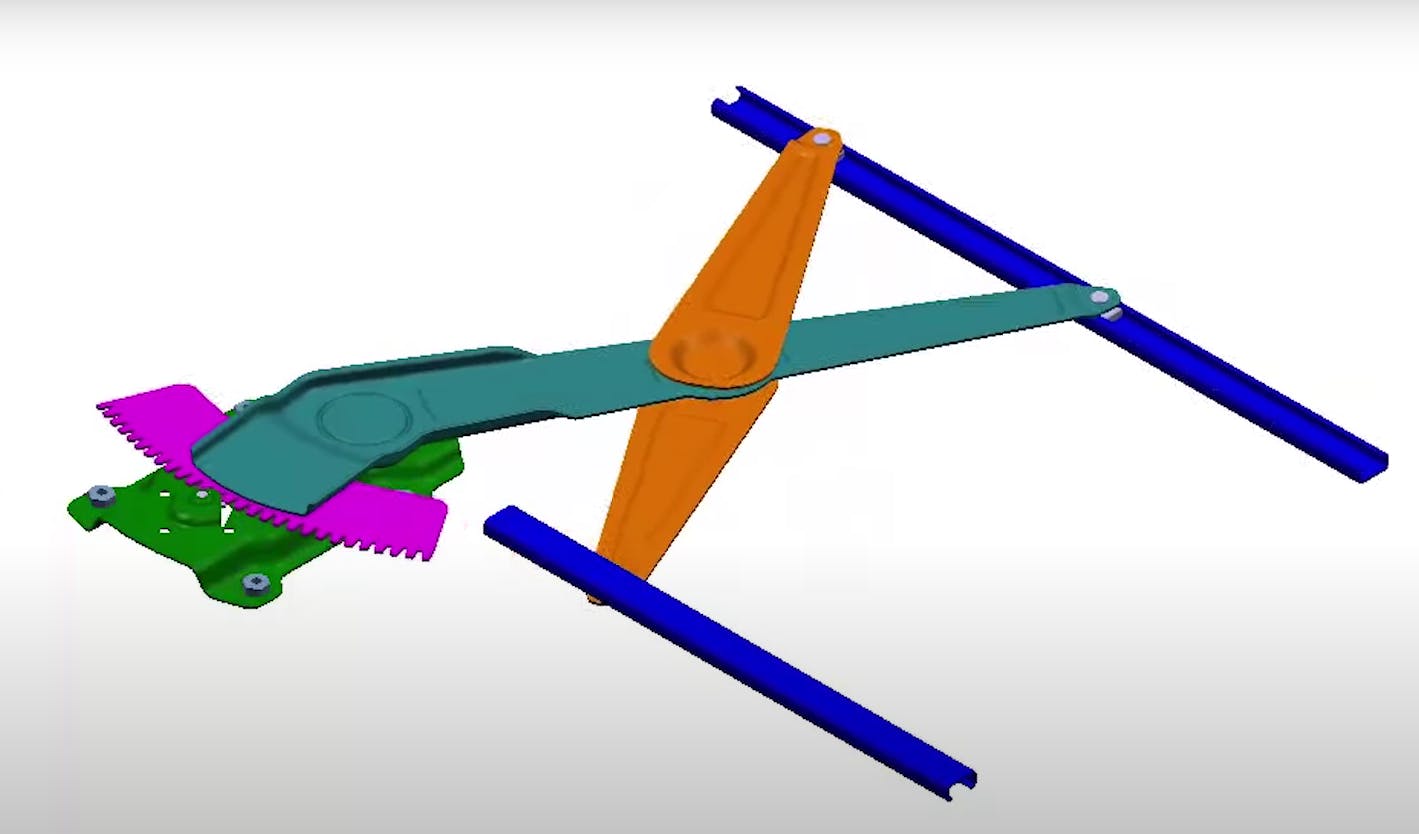

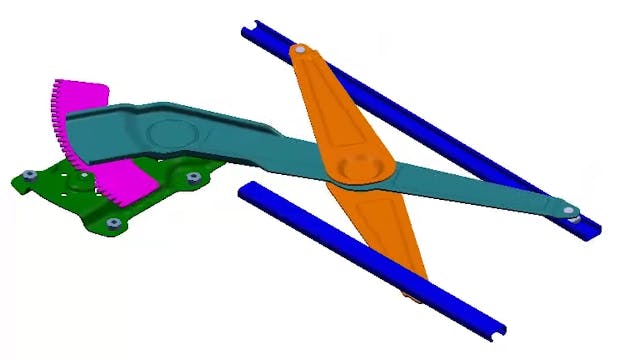

design engineers often worked with Freebody diagram and BMD which comes under statics in process of designing the mechanisms design engineers work on various kind of

![RH Design - 5 Most Important Skills For Every Mechanical Design Engineer To Get a Dream Job & Career RH Design [dcZ2jAoa0ok - 1046x588 - 2m46s].png](https://cdn.hashnode.com/res/hashnode/image/upload/v1660037893933/lyIwBuvQ3.png?auto=compress,format&format=webp)

matrix values such as velocity, acceleration, and displacement of various components shown is an example of a mechanism whereby putting efforts on a component shown is an example of a mechanism whereby putting efforts on a pinion and gear sector rotating movement is converting into up and down movement of rail

3. Materials

The third skill on our list is 'material' which is "the science and engineering of materials" now one might ask here -> why material knowledge is important for design engineers.

![RH Design - 5 Most Important Skills For Every Mechanical Design Engineer To Get a Dream Job & Career RH Design [dcZ2jAoa0ok - 1046x588 - 3m09s].png](https://cdn.hashnode.com/res/hashnode/image/upload/v1660038666089/wz2XggVz9.png?auto=compress,format&format=webp)

So let me tell you 'design engineering' is not just about creating shapes and geometry of a product but way more than that you have to understand the purpose

and

application of your product and what boundary conditions it will be working on what would be environmental conditions: will it be exposed to heavy rain

or

heat is their chances of corrosion do I need to consider coating all of it is a part of designing engineering process.

Let me further explain it with an example this is an

![RH Design - 5 Most Important Skills For Every Mechanical Design Engineer To Get a Dream Job & Career RH Design [dcZ2jAoa0ok - 1046x588 - 3m43s].png](https://cdn.hashnode.com/res/hashnode/image/upload/v1660039097699/D42nyUmpn.png?auto=compress,format&format=webp) automobile car door latch and this one is the Striker both of them engage together to lock the door successfully.

automobile car door latch and this one is the Striker both of them engage together to lock the door successfully.

Designing the latch is not just about:

Creating its shape but you have to consider what would be the load on the latch,

you have to consider the weight of the door, how far the door hinge is to sustain the load,

what material should be made of, in which countries vehicle would be launching in are there any extreme weather conditions you have to factor in all of it before starting your design and material knowledge is very critical.

Important mechanical properties of materials

![RH Design - 5 Most Important Skills For Every Mechanical Design Engineer To Get a Dream Job & Career RH Design [dcZ2jAoa0ok - 939x528 - 4m24s].png](https://cdn.hashnode.com/res/hashnode/image/upload/v1660039635203/yE1282g3-.png?auto=compress,format&format=webp)

- Strength

- Hardness

- Toughness

- Elasticity

- Stiffness

4. Manufacturing Processes

- Production of Products using various processes

![RH Design - 5 Most Important Skills For Every Mechanical Design Engineer To Get a Dream Job & Career RH Design [dcZ2jAoa0ok - 939x528 - 4m36s].png](https://cdn.hashnode.com/res/hashnode/image/upload/v1660039864178/eoqaC63ar.png?auto=compress,format&format=webp) after design product has to be manufactured with one of the available manufacturing processes

after design product has to be manufactured with one of the available manufacturing processes

so while the design itself engineer has to consider these facts and that is where the methods like the design for manufacturing, and design for assembly come in every manufacturing process and

machinery has limited capabilities and some limitations which should be considered in the design phase itself tolerances are also given.

In accordance with that only here are some of the manufacturing processes which every design engineer has to have a good understanding on:

![RH Design - 5 Most Important Skills For Every Mechanical Design Engineer To Get a Dream Job & Career RH Design [dcZ2jAoa0ok - 939x528 - 5m18s].png](https://cdn.hashnode.com/res/hashnode/image/upload/v1660040261377/xmtpMeKt9.png?auto=compress,format&format=webp)

5. Cost

Cost - Finding how much it will cost for the company to make the product.

In the end, everything comes down to cost no matter how good or effective your design is if it has not cost competitive it is not good to be successful

nobody can deny the fact one part of successfully running an organization is about managing its "finances and profits"

![RH Design - 5 Most Important Skills For Every Mechanical Design Engineer To Get a Dream Job & Career RH Design [dcZ2jAoa0ok - 939x528 - 5m40s].png](https://cdn.hashnode.com/res/hashnode/image/upload/v1660040679209/aL2oEjInS.png?auto=compress,format&format=webp)

as we know profits are directly dependent on cost so designing a cost-competitive product is one of the keys.

Product Cost Estimation

Responsibilities of design engineers good starting point for cost would be to have an understanding of product cost estimation.

Mainly there are direct and indirect costs some of the important cost components are Material costs,

![RH Design - 5 Most Important Skills For Every Mechanical Design Engineer To Get a Dream Job & Career RH Design [dcZ2jAoa0ok - 939x528 - 6m10s].png](https://cdn.hashnode.com/res/hashnode/image/upload/v1660040921397/nI61R6aMc.png?auto=compress,format&format=webp)

Process cost, CAPEX, and Transportation cost.

So these were the five most important skills.